Foam Gasket

HON HAMN is equipped the Automatic Adhesive Processing Machine for foam gasket incorporates several steps in one production line. Based on the coating process, the liquid acrylic adhesives is coated to a substrate, then immediately laminated to a second substrate via a nip followed by taking into the oven for heat-drying at high temperature so that it is ready to be rewound as a complete foam gasket.

To increase efficiency in your facility and decrease downtime in your production process by using long-length reels. HON HAMN offers customized length and widths reels with a variety of foam to support your multiple applications.

The maximum width of foam is with 8 mm, capable of ± 1mm in tolerance.

HON HAMN can cut foam into sheet and laminate another material such as protective film on either sides or one side with the size requested by customers as the Width available up to 1.2 meters and 32 kg/m3 in Density.

HON HAMN utilize several processing techniques, so we are able to choose the process best suited to the product characteristics. The process can apply adhesive foam to foam such as PU, PE, and PET. Different materials can also be bonded together such as foam to Aluminum or PVC. We can match customer's needs by our technology know-how.

Our working process can laminate foam while controlling curl by the selection of adhesive and the unique technology, no occurrence of voids bubbles between the interlayer.

HON HAMN provides the secondary manufacturing processes of standard and custom foam tubing ideal in minimum thickness of 5mm for reducing vibration. Available in various sizes and serves the HVAC and manufacturing industries with UL certified.

HON HAMN products are often coated with “Acrylic Adhesives”. They offer performance advantages over other types of compositions. Acrylic Adhesives exhibit good ultraviolet and exterior durability, excellent chemical resistance under a broad range of temperatures. These adhesives are typically characterized by peel and shear.

HON HAMN is equipped with multiple slitting capabilities across several machines to produce the highest quality converted rolls for each of your diverse applications, whether you need ultra-thin 8 mm wide width for laminating or the maximum thickness of foam with 8 mm, capable of ± 1mm in tolerance, we have the flexibility to slit a wide assortment of materials regardless of their raw dimensions.

Since die cutting foam involves compressing the foam, a certain amount of distortion is to be expected. We die cut PU, PE and rubber materials serving multiple end users including general industrial and household. Our design team will work with you to determine the best materials for your project.

HON HAMN Customized Die Cutting

HON HAMN Automatic Adhesive Processing Machine for Foam Gasket.

Equipment List

-

Hydraulic Press Cutting Machine

MK-530AG QTY: 4 -

Hydraulic Press Cutting Machine

MK-530BD QTY: 4 -

Vertical Cutting Machine

CFM-03BL QTY: 9 -

Coating Machine

MD-205J7 QTY: 1 -

Laminating Machine

MD-706J QTY: 1 -

C-type Dynamic Power Press

NCP-15 QTY: 1 -

Continuous Cutting Machine

High speed TECO QTY: 2 -

Slitter Rewinder

Custom Product QTY: 1 -

Slitter Rewinder

EG1A QTY: 1 -

Cutting Machine

TECHJOY.M/F QTY: 3 -

Cutting Machine

MD-500A QTY: 1 -

Profile Cutting Machine

SUNRIST QTY: 1 -

Automatic Pipe Cutting Machine

MD 400A QTY: 1 -

Pipe Cutting Machine

CAMEL QTY: 1

Steel

Hon hamn Foam:

PORON®, CR, NBR, SBR, EVA, PE, PU, AEPE, CEPE, wool felt, dust cover....etc. Everything accurate needed is here

| TYPE | GENERIC | MODEL | DENSITY(Kg/m3) | MAX-WIDTH(mm) | FEATURES |

| PU | 01 | ABUL | 32 | 1,230 | Insulation |

| 02 | ADUL | 23.5 | 1,230 | ||

| 03 | ADAUL | 20.5 | 1,230 | ||

| 04 | T15UL | 14 | 1,230 | ||

| 05 | T45HUL | 43.6 | 1,230 | ||

| 06 | T28UK | 28.4 | 1,230 | ||

| 07 | PU FILTER | 19.3 | 1,000 | ||

| 08 | AL PET+ADAUL | 20.5 | 1,200 | ||

| PE | 01 | AEPEUL | 32.4 | 1,230 | |

| 02 | CEPEUL | 31.9 | 1,230 | ||

| 03 | EPE | 18.7 | 1,000 | ||

| 04 | EPE_ANTI-STATIC | 22.2 | 1,000 | ||

| 05 | AEPE | 66.7±8 | 1,870 | ||

| 06 | CEPEUL+Aluminum Foil | 28.6±2 | 1,200 | ||

| 07 | EVA | 96.2 | 1,000 | ||

| 08 | PE(CONDUCTIVITY) | 30-45 | 1,000 | ||

| SPECIAL | 01 | RBUL | 60~80 | 1,200 | |

| 02 | VS-100F | 50~70 | 1,200 | ||

| 03 | SBR | 72.7 | 1,200 | ||

| 04 | RB TUBE | 60~80 | 1000 | ||

| 05 | CR4305 | 207.7 | 1,000 | ||

| 06 | HIMELON | 1,000 | |||

| 07 | CARBON FILTER | 34.5 | 1,000 |

X FOAM:

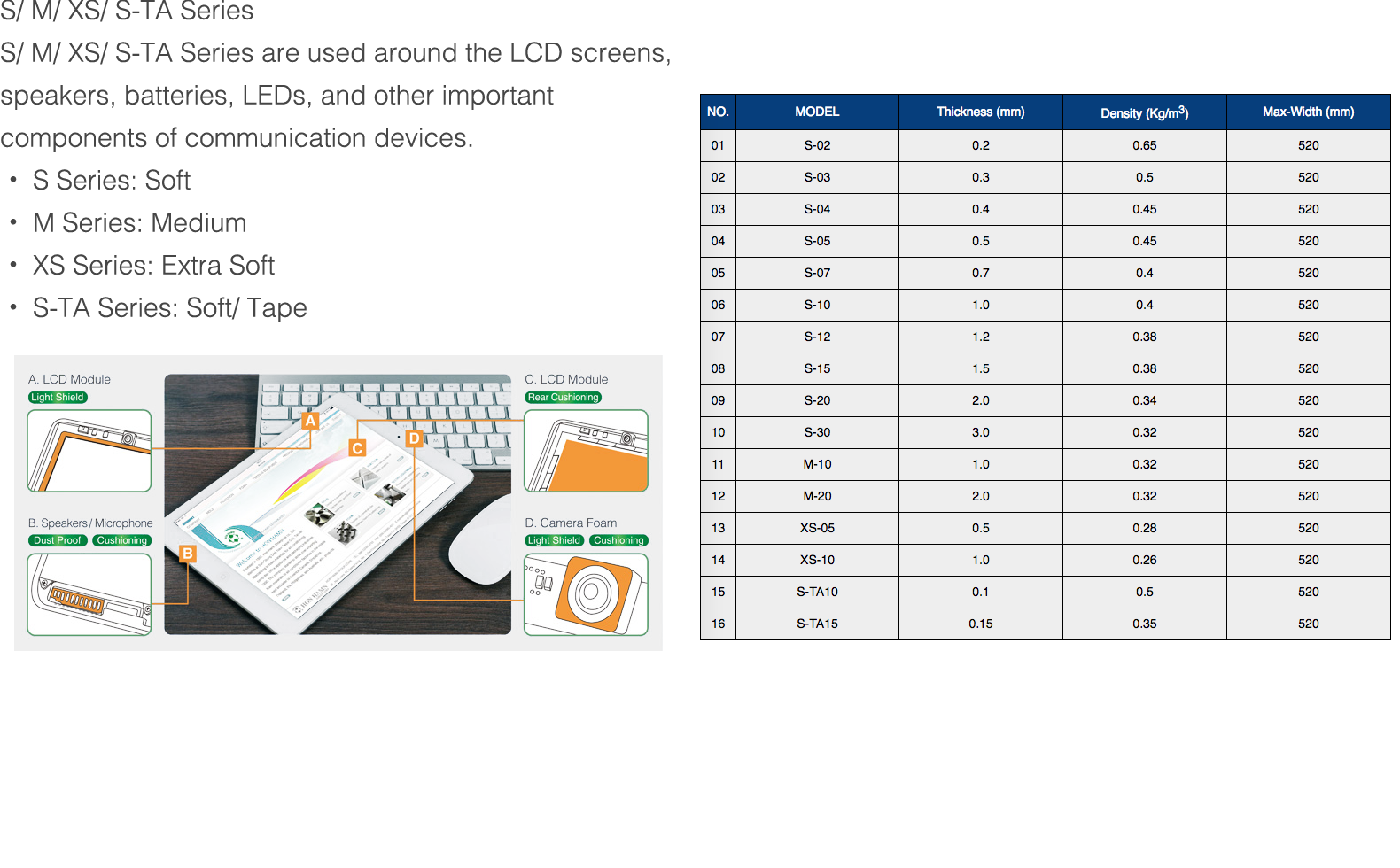

S/ M/ XS/ S-TA Series

S/ M/ XS/ S-TA Series are used around the LCD screens, speakers, batteries, LEDs, and other important components of communication devices.

・S Series: Soft

・M Series: Medium

・XS Series: Extra Soft

・S-TA Series: Soft/ Tape

| NO. | MODEL | Thickness (mm) | Density (Kg/m3) | Max-Width (mm) |

| 01 | S-02 | 0.2 | 0.65 | 520 |

| 02 | S-03 | 0.3 | 0.5 | 520 |

| 03 | S-04 | 0.4 | 0.45 | 520 |

| 04 | S-05 | 0.5 | 0.45 | 520 |

| 05 | S-07 | 0.7 | 0.4 | 520 |

| 06 | S-10 | 1.0 | 0.4 | 520 |

| 07 | S-12 | 1.2 | 0.38 | 520 |

| 08 | S-15 | 1.5 | 0.38 | 520 |

| 09 | S-20 | 2.0 | 0.34 | 520 |

| 10 | S-30 | 3.0 | 0.32 | 520 |

| 11 | M-10 | 1.0 | 0.32 | 520 |

| 12 | M-20 | 2.0 | 0.32 | 520 |

| 13 | XS-05 | 0.5 | 0.28 | 520 |

| 14 | XS-10 | 1.0 | 0.26 | 520 |

| 15 | S-TA10 | 0.1 | 0.5 | 520 |

| 16 | S-TA15 | 0.15 | 0.35 | 520 |

GASKA:

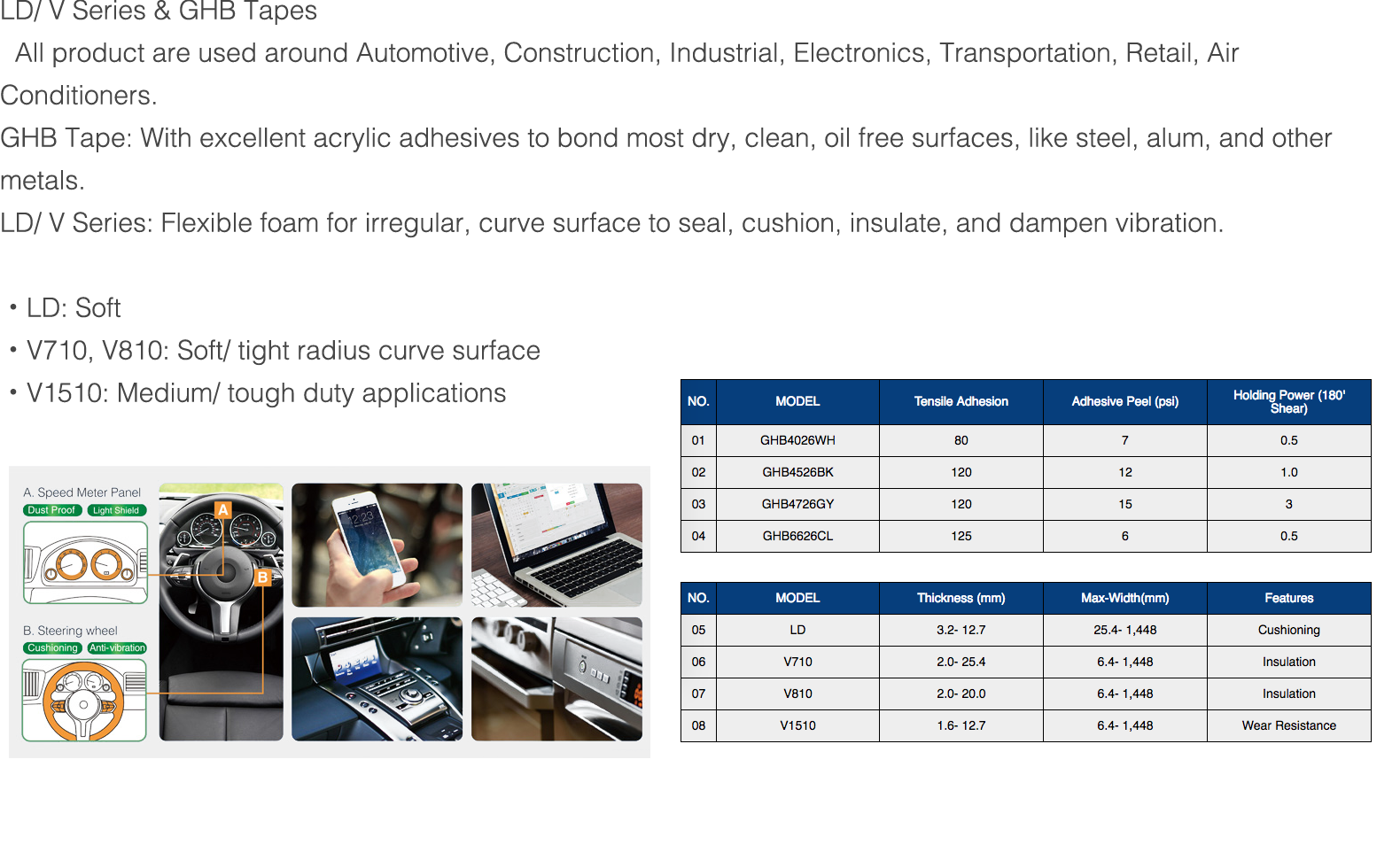

LD/ V Series & GHB Tapes

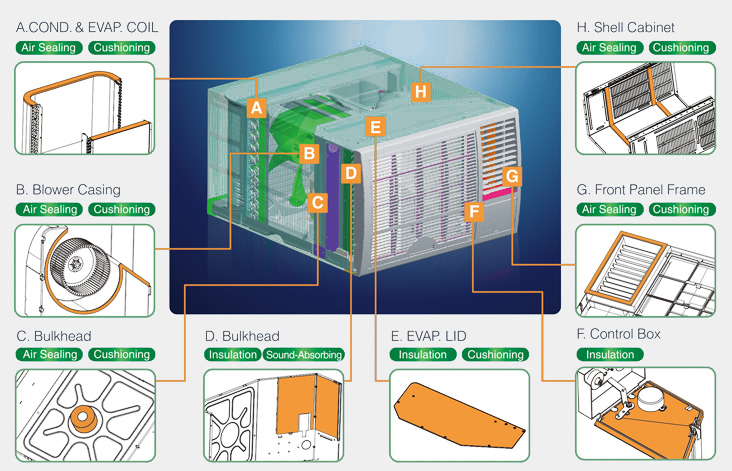

All product are used around Automotive, Construction, Industrial, Electronics, Transportation, Retail, Air Conditioners.

GHB Tape: With excellent acrylic adhesives to bond most dry, clean, oil free surfaces, like steel, alum, and other metals.

LD/ V Series: Flexible foam for irregular, curve surface to seal, cushion, insulate, and dampen vibration.

・LD: Soft

・V710, V810: Soft/ tight radius curve surface

・V1510: Medium/ tough duty applications

| NO. | MODEL | Tensile Adhesion | Adhesive Peel (psi) |

Holding Power (180' Shear) |

| 01 | GHB4026WH | 80 | 7 | 0.5 |

| 02 | GHB4526BK | 120 | 12 | 1.0 |

| 03 | GHB4726GY | 120 | 15 | 3 |

| 04 | GHB6626CL | 125 | 6 | 0.5 |

| NO. | MODEL | Thickness(mm) | Max-Width(mm) | Features |

| 05 | LD | 3.2- 12.7 | 25.4- 1,448 | Cushioning |

| 06 | V710 | 2.0- 25.4 | 6.4- 1,448 | Insulation |

| 07 | V810 | 2.0- 20.0 | 6.4- 1,448 | Insulation |

| 08 | V1510 | 1.6- 12.7 | 6.4- 1,448 | Wear Resistance |

| Q1 |

Are you trading company or factory ?

Are you trading company or factory ?

HON HAMN's Headquarter and R&D Dept. is located in Taiwan, and Our Factory is located in Dongguan, GuangDong Province, China. |

| Q2 |

How can I ensure my technical information and know-how will be protected?

How can I ensure my technical information and know-how will be protected?

We can sign NDA's agreement (Non-Disclosure Agreements) to restrict the usage and additional disclosure of the shared information, knowledge, or materials. |

| Q3 |

I have an idea/ sample but don’t have drawing, what can I do?

I have an idea/ sample but don’t have drawing, what can I do?

Please share the project detail to us, and we can provide ON STOP SERVICE. |

| Q4 |

What type of files can you accept?

What type of files can you accept?

STP, IGS, DWG, DXF. |

| Q5 |

Your trading terms ?

Your trading terms ?

EX-WORKS, FOB, CIF, DDP, DDU |

| Q6 |

Your payment terms ?

Your payment terms ?

For plastic injection molds and metal stamping dies : 30% T/T in advance before starting design & 70% T/T before shipment. |

| Q7 |

Are you Foam Manufacturer or Processing Company?

Are you Foam Manufacturer or Processing Company?

We provide foam gasket with adhesive and other processing. |

| Q8 |

What materials are available to produce from your side?

What materials are available to produce from your side?

PE/ PU/ RUBBER/Low Density Foam/PVC, etc. Everything accurate needed is here. |

| Q9 |

What is your sample policy?

What is your sample policy?

We can offer free samples of small sizes for Standard Material and Thickness, but customers have to pay the delivery cost. |

| Q10 |

What information should I give to you for inquiry?

What information should I give to you for inquiry?

1) Product Drawing |