HON HAMN Group Corp.

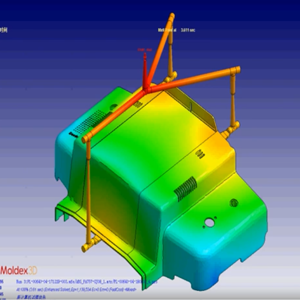

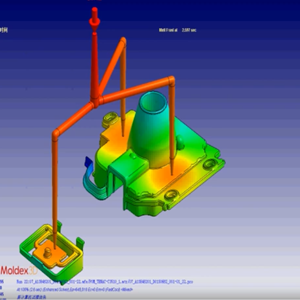

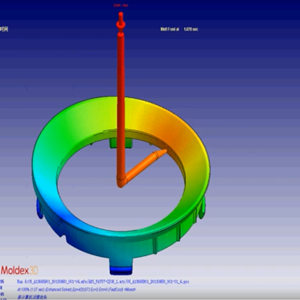

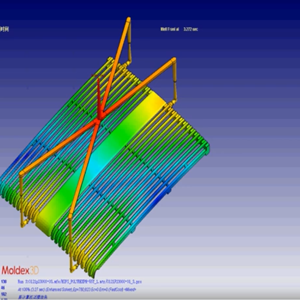

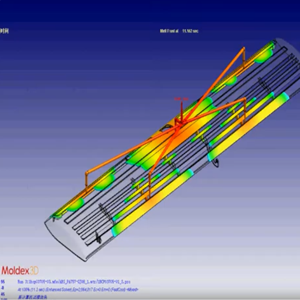

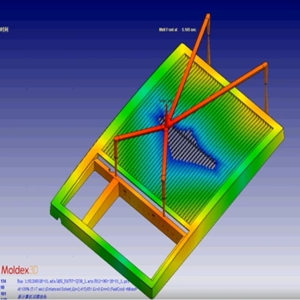

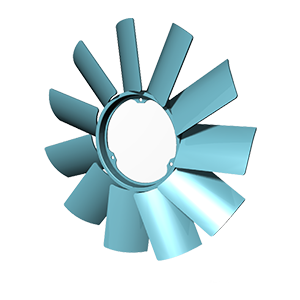

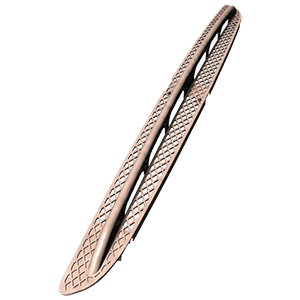

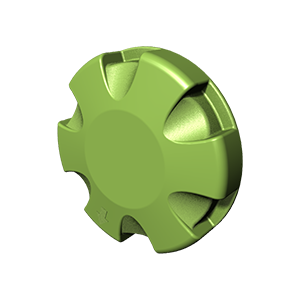

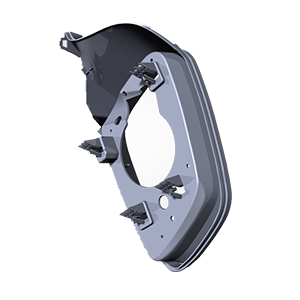

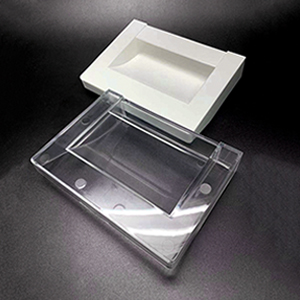

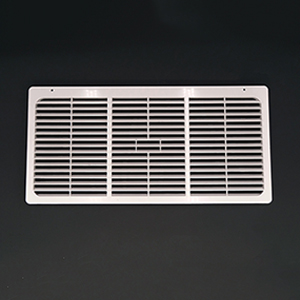

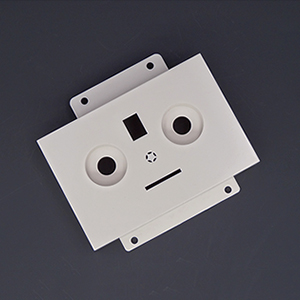

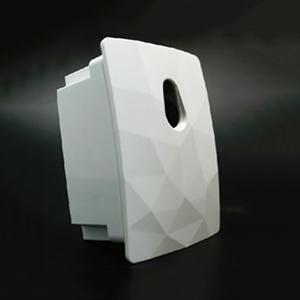

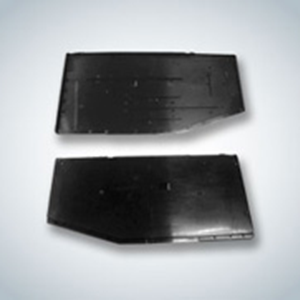

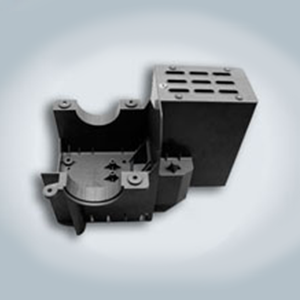

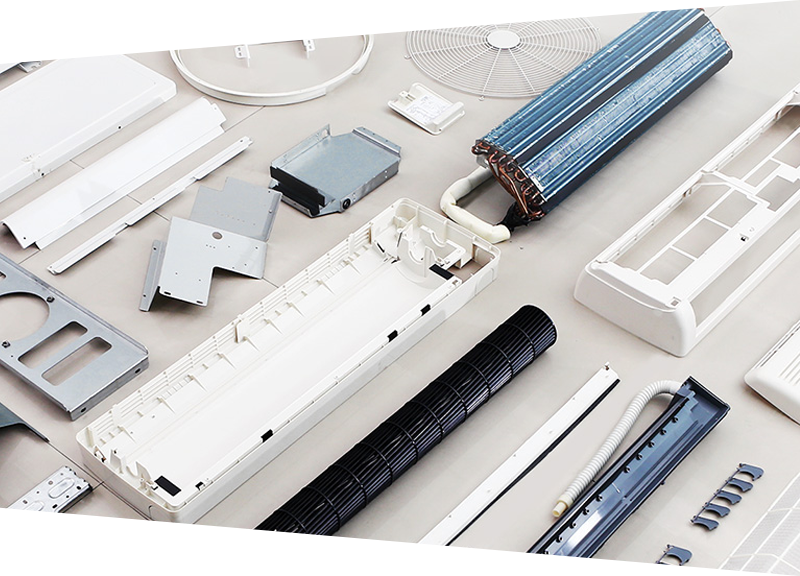

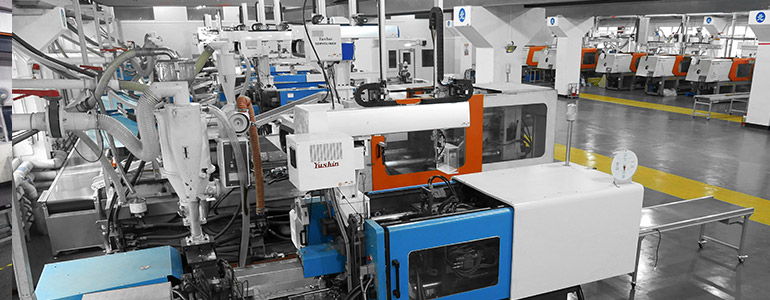

HON HAMN was founded in 1987 in Taipei, Taiwan for plastic injection mold and metal stamping die manufacturing, plastic injection production, and foam gasket processing.

HIGH QUALITY, GOOD SERVICE, COMPETITIVE PRICE are the top priority objects. HON HAMN has experienced English-speaking project managers and highly skilled professional engineering teams of designers, toolmakers, and machinists on appearance design, 2D/3D mechanical structure design, plastic injection mold design, sheet metal pressing die design, injection production, product assembly, and mass customization in order to provide high standard of ODM and OEM services.

HON HAMN strives to provide the best product in accordance with the customers’ precise specifications. Our customers mean everything to HON HAMN. We collaborate with the customers to deliver innovative solutions to manufacturing problems. HON HAMN reputation for excellence has been built on our ability to provide our valued customers with the most effective manufacturing solutions to meet their most demanding applications.

Read More