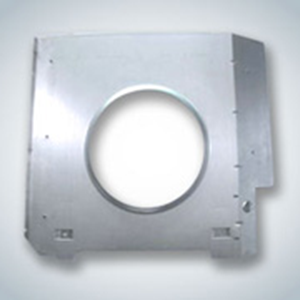

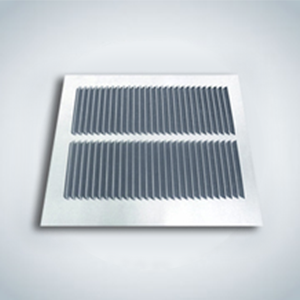

金属板金型

Hon Hamnは白家電製品の板金プレス金型の開発と製造に特化して、固定金型と順送金型を提供している。最大寸法は2000mm(L)×1200mm(W)で、400トンのプレス機械に適合する

お客様提供のサンプルや設計図面に基づいて、カスタマイズの設計を行う。開発の段階において、2次元と3次元の専門ソフトウェアを生かして、製品全体の組合せや設計最適化などのエンジニアリングサービスを提供する。このお陰で、製造後の設計変更を避け、安定した生産品質を改善し、金型の寿命を延ばすことができる

プレス金型が皆入れ子設計なので、ユーザサイドではメンテナンスを迅速に行われる。先進的なワイヤカット、放電加工機、CNCなどの専門設備を持っており、新技術の学習と教育訓練を持続的に推進し、金型の製造能力をアップさせ、加工機械にも投資する。金型に最高の品質、最高のサービス、最も競争力のある価格を提供できる

清潔で明るく、安全な作業環境において、様々な型加工設備で精密でかつ安定した生産をする

先進的なワイヤカット、放電加工機、マシニングセンター

専業的な固定と順送板金プレス金型

設備リスト

-

CNC Machining Center

TV-158B QTY: 1 -

High Speed CNC Machining Center

AV-70S QTY: 2 -

High Speed CNC Machining Center

AV-128 QTY: 2 -

CNC Drill

A-T21iEe QTY: 2 -

Milling Machine

QJM-S2 QTY: 3 -

Milling Machine

NSG-5A QTY: 1 -

Milling Machine

NSG-5AV QTY: 1 -

Wire Cutting Machine

CW-640HS QTY: 1 -

Wire Cutting Machine

DC7740 QTY: 1 -

Wire Cutting Machine

Seibu-M75B QTY: 1 -

EDM

E 600 QTY: 1 -

EDM

P 350 QTY: 1 -

EDM

M50F QTY: 2 -

EDM

T60 ZNC QTY: 2 -

EDM

T120 ZNC QTY: 1 -

EDM

CM-H32A QTY: 1 -

EDM

CMH86C QTY: 1 -

Surface Grinder

TSG-350 QTY: 2 -

Surface Grinder

KGS-63AHD QTY: 2 -

Surface Grinder

KGS-510AHD QTY: 1 -

Lathe

CH 530*800 QTY: 1 -

Radial Drill

TPR-1230H QTY: 1 -

Metal Bandsaw Machine

G4-9169 QTY: 1 -

Laser Engraver

H-SGH-20 QTY: 1 -

WorkPartner 1+

WPT 1+ QTY: 1

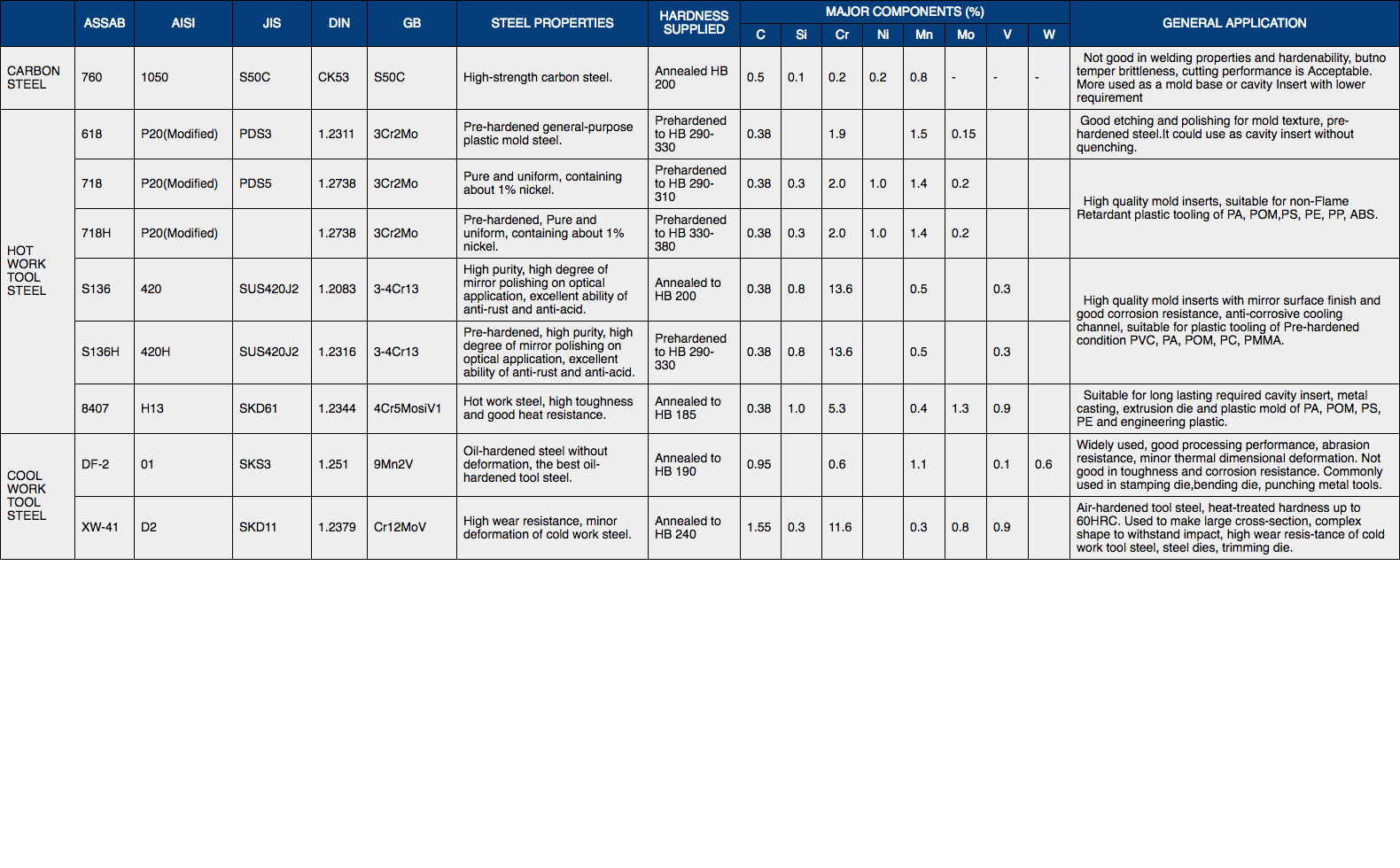

Steel

| ASSAB | AISI | JIS | DIN | GB | STEEL PROPERTIES | HARDNESS SUPPLIED | MAJOR COMPONENTS (%) | GENERAL APPLICATION | ||||||||

| C | Si | Cr | Ni | Mn | Mo | V | W | |||||||||

| CARBON STEEL | 760 | 1050 | S50C | CK53 | S50C |

High-strength carbon steel.

|

Annealed HB 200 | 0.5 | 0.1 | 0.2 | 0.2 | 0.8 | - | - | - |

Not good in welding properties and hardenability, butno temper brittleness, cutting performance is Acceptable. More used as a mold base or cavity Insert with lower requirement

|

| HOT WORK TOOL STEEL | 618 | P20(Modified) | PDS3 | 1.2311 | 3Cr2Mo |

Pre-hardened general-purpose plastic mold steel.

|

Prehardened to HB 290-330 | 0.38 | 1.9 | 1.5 | 0.15 |

Good etching and polishing for mold texture, pre-hardened steel.It could use as cavity insert without quenching.

|

||||

| 718 | P20(Modified) | PDS5 | 1.2738 | 3Cr2Mo |

Pure and uniform, containing about 1% nickel.

|

Prehardened to HB 290-310 | 0.38 | 0.3 | 2.0 | 1.0 | 1.4 | 0.2 |

High quality mold inserts, suitable for non-Flame Retardant plastic tooling of PA, POM,PS, PE, PP, ABS.

|

|||

| 718H | P20(Modified) | 1.2738 | 3Cr2Mo |

Pre-hardened, Pure and uniform, containing about 1% nickel.

|

Prehardened to HB 330-380 | 0.38 | 0.3 | 2.0 | 1.0 | 1.4 | 0.2 | |||||

| S136 | 420 | SUS420J2 | 1.2083 | 3-4Cr13 |

High purity, high degree of mirror polishing on optical application, excellent ability of anti-rust and anti-acid.

|

Annealed to HB 200 | 0.38 | 0.8 | 13.6 | 0.5 | 0.3 |

High quality mold inserts with mirror surface finish and good corrosion resistance, anti-corrosive cooling channel, suitable for plastic tooling of Pre-hardened condition PVC, PA, POM, PC, PMMA.

|

||||

| S136H | 420H | SUS420J2 | 1.2316 | 3-4Cr13 |

Pre-hardened, high purity, high degree of mirror polishing on optical application, excellent ability of anti-rust and anti-acid.

|

Prehardened to HB 290-330 | 0.38 | 0.8 | 13.6 | 0.5 | 0.3 | |||||

| 8407 | H13 | SKD61 | 1.2344 | 4Cr5MosiV1 |

Hot work steel, high toughness and good heat resistance.

|

Annealed to HB 185 | 0.38 | 1.0 | 5.3 | 0.4 | 1.3 | 0.9 |

Suitable for long lasting required cavity insert, metal casting, extrusion die and plastic mold of PA, POM, PS, PE and engineering plastic.

|

|||

| COOL WORK TOOL STEEL | DF-2 | 01 | SKS3 | 1.251 | 9Mn2V |

Oil-hardened steel without deformation, the best oil-hardened tool steel.

|

Annealed to HB 190 | 0.95 | 0.6 | 1.1 | 0.1 | 0.6 |

Widely used, good processing performance, abrasion resistance, minor thermal dimensional deformation. Not good in toughness and corrosion resistance. Commonly used in stamping die,bending die, punching metal tools.

|

|||

| XW-41 | D2 | SKD11 | 1.2379 | Cr12MoV |

High wear resistance, minor deformation of cold work steel.

|

Annealed to HB 240 | 1.55 | 0.3 | 11.6 | 0.3 | 0.8 | 0.9 |

Air-hardened tool steel, heat-treated hardness up to 60HRC. Used to make large cross-section, complex shape to withstand impact, high wear resis-tance of cold work tool steel, steel dies, trimming die.

|

|||

| Q1 |

Are you trading company or factory ?

Are you trading company or factory ?

HON HAMN's Headquarter and R&D Dept. is located in Taiwan, and Our Factory is located in Dongguan, GuangDong Province, China. |

| Q2 |

How can I ensure my technical information and know-how will be protected?

How can I ensure my technical information and know-how will be protected?

We can sign NDA's agreement (Non-Disclosure Agreements) to restrict the usage and additional disclosure of the shared information, knowledge, or materials. |

| Q3 |

I have an idea/ sample but don’t have drawing, what can I do?

I have an idea/ sample but don’t have drawing, what can I do?

Please share the project detail to us, and we can provide ON STOP SERVICE. |

| Q4 |

What type of files can you accept?

What type of files can you accept?

STP, IGS, DWG, DXF. |

| Q5 |

Your trading terms ?

Your trading terms ?

EX-WORKS, FOB, CIF, DDP, DDU |

| Q6 |

Your payment terms ?

Your payment terms ?

For plastic injection molds and metal stamping dies : 30% T/T in advance before starting design & 70% T/T before shipment. |

| Q7 |

What type of metal stamping die do you make?

What type of metal stamping die do you make?

Stationary Dies, Family Dies and Progressive Dies. |

| Q8 |

What information should I give to you for inquiry?

What information should I give to you for inquiry?

1) 2D/3D drawing |

| Q9 |

What is your advantage?

What is your advantage?

Our steel material are all certified with BRAND and imported from German and Japan for stronger and stable quality. |