MASS CUSTOMIZATION

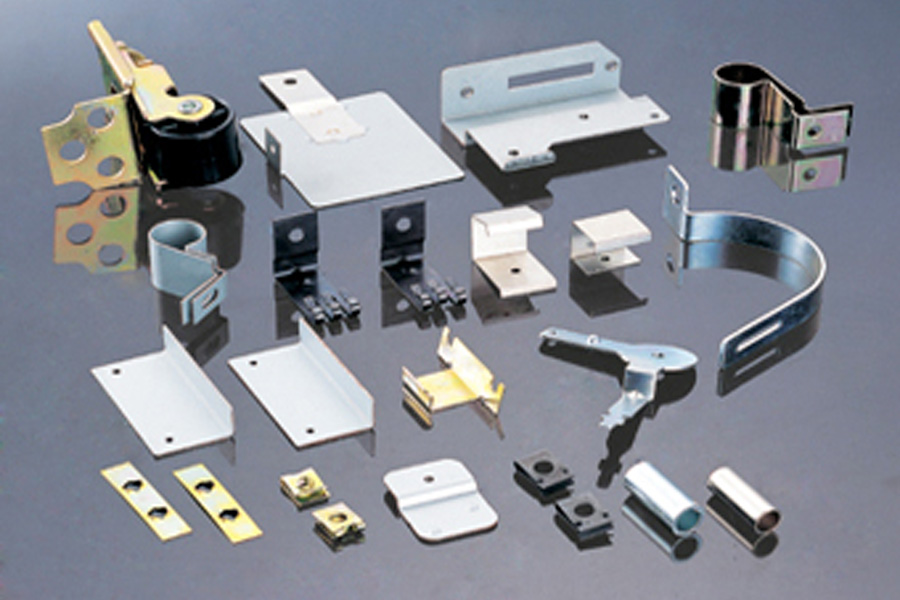

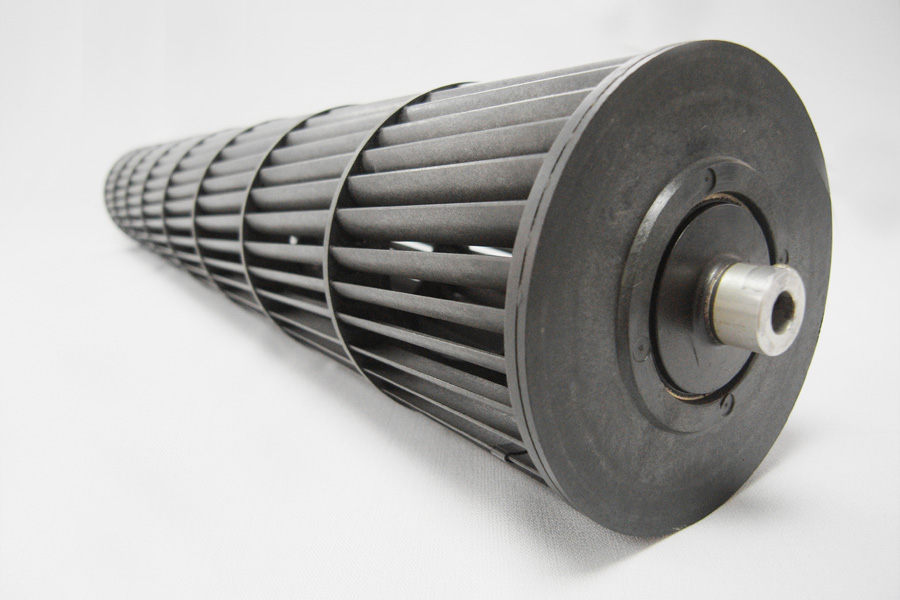

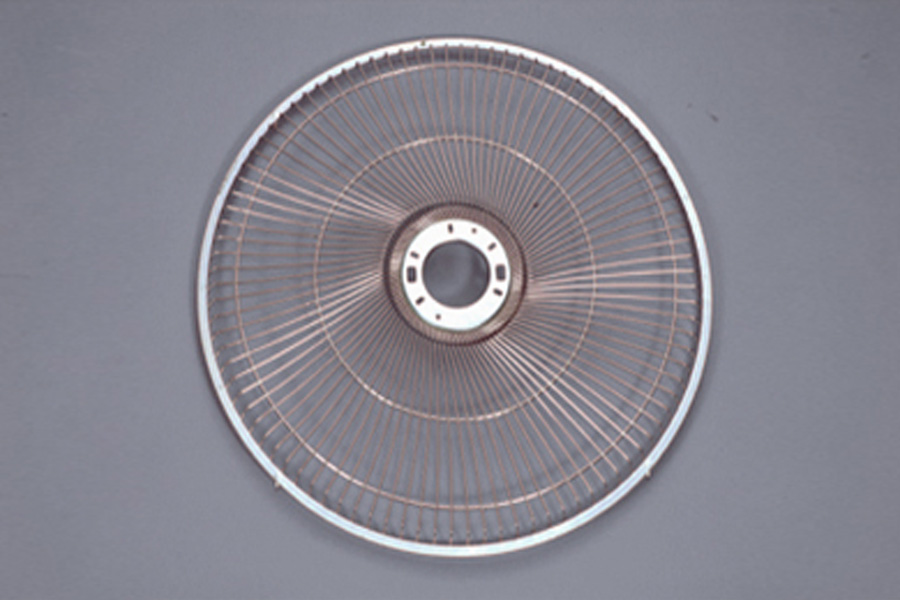

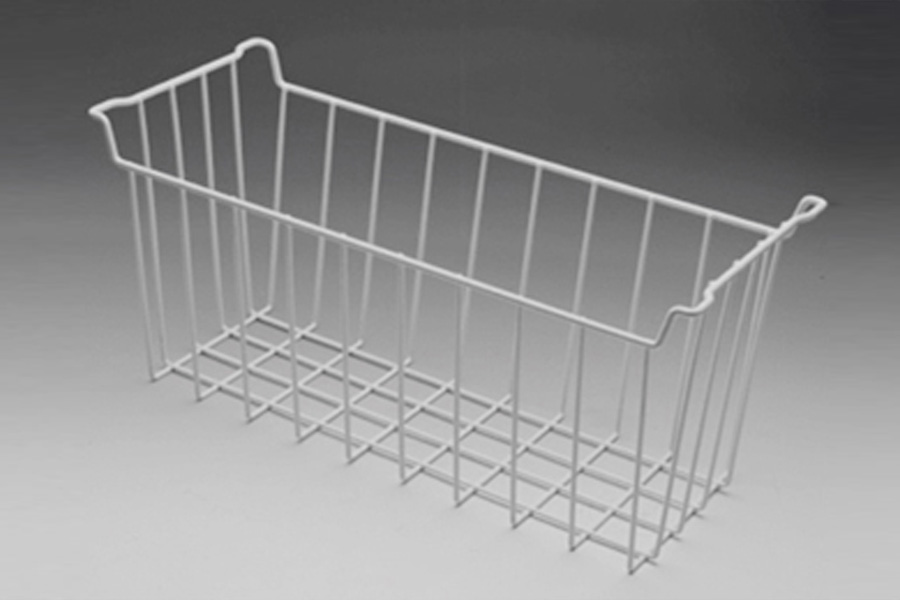

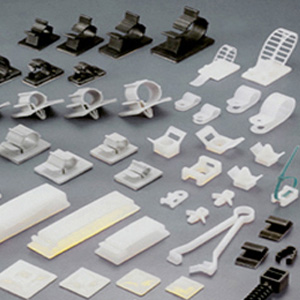

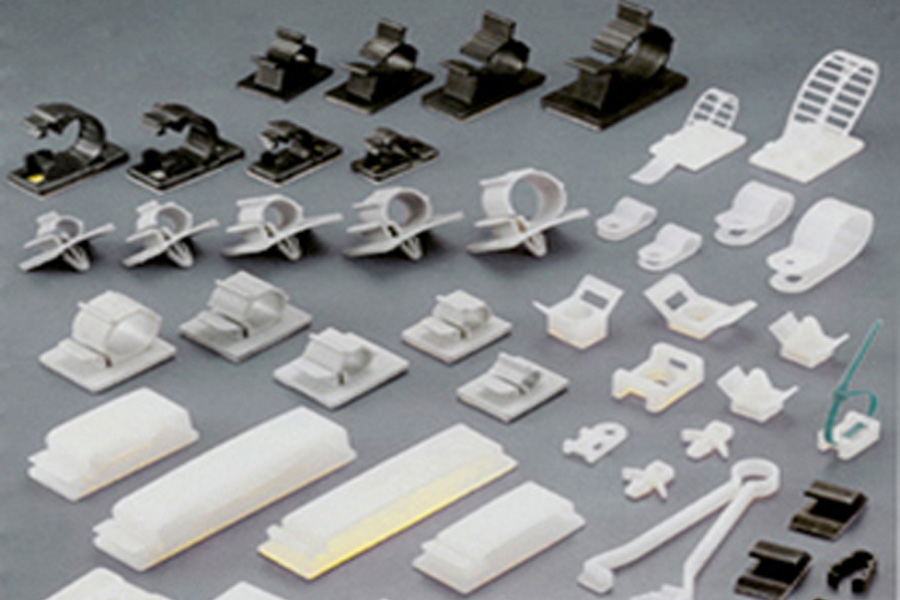

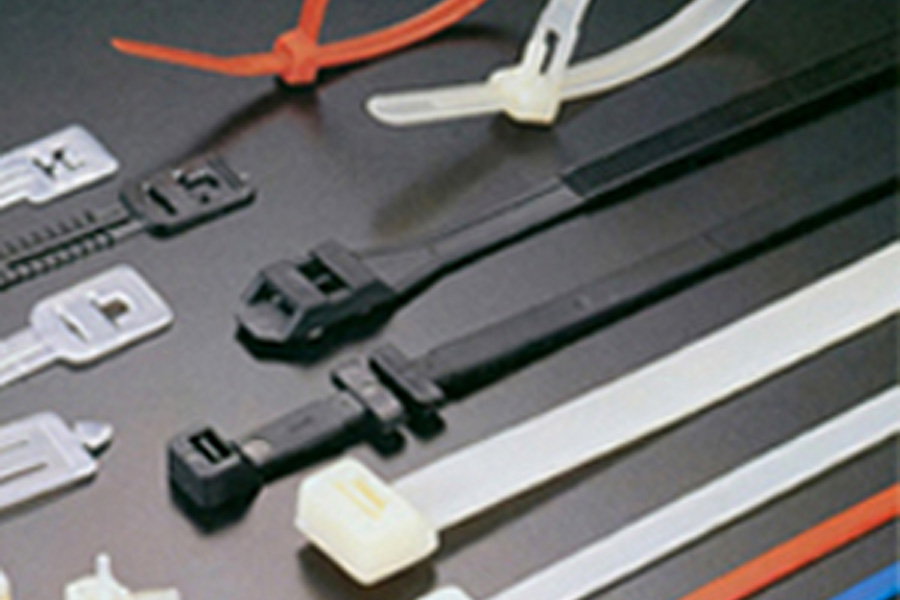

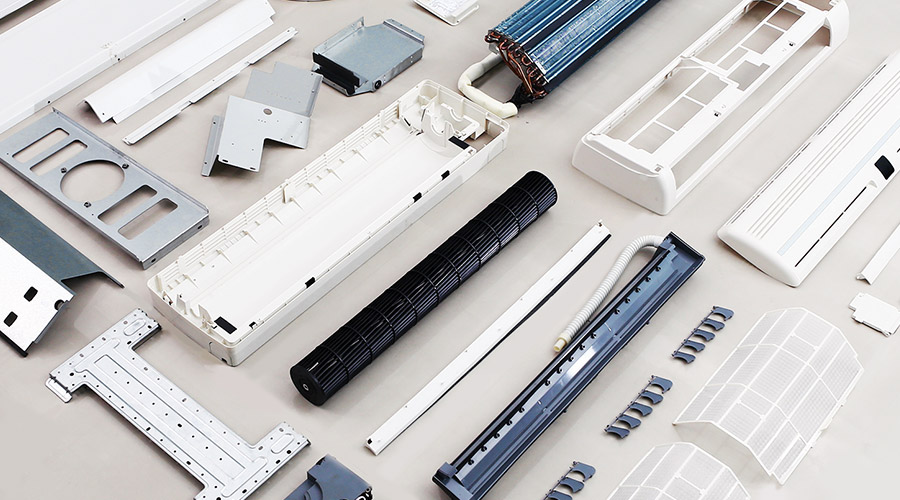

Based on customer needs, HON HAMN can provide assembly service, contract mass customization on parts or manufacturing machines. HON HAMN is a complete manufacturing solution provider with passion to commit to consistently meet all customers’ drawing specifications and tolerance requirements.

Value Added Secondary Processes

Transferring the ink of custom-colored graphics from a silicone pad onto the surface of the item you want printed.

Forcing the ink of custom-colored graphics through a stencil onto the surface of the item with a squeegee.

HON HAMN partner, Special Coatings GmbH & Co. KG, is one of the global leaders in the field of surface coating by using drum coating technology. Since the introduction of the SC-Coater® drum coating machine in 2005, Special Coatings enjoys an outstanding reputation on the world market as an experienced system supplier for drum coating equipment as well as customized lacquering and coating material for the decorative and functional coating of mass - produced small parts and bulk material. (https://www.special-coatings.com/en/)

Using stamping press engages the heated die or tool with the custom-colored graphics foil and transfers the ink from the foil press onto the part to be marked.

Using high-frequency ultrasonic creates molecular heat to softening or melting thermoplastic materials to join/reform/stick components together with amazing welding strength.

Using a heated plate to melt the joining surfaces of the two thermoplastic parts. Remove heated plate when the joined surfaces are melted, bring joined surfaces together until plastic parts are welded. This technique allows large and complex component to be joined with amazing welding strength.

Using the machine to heat the metal inserts (screws or nuts) and press into the plastic parts.

Assemble components by employing heat and force to melt and deform the studs of plastic component. Components are mechanically locked together securely without using extra metal screws for less cost on material and assembly.

HON HAMN has various of in-house machines such as lathes, CNC machines, wire cutting machines and EDM. We offer a wide range of high-quality services to perform secondary process requirements from customers.

The surface of the plastic component is coated with metallic colors from an electroless plating solution for decorative purposes. The shining metallic colors can be chrome, nickel, copper, silver, brass, black or gold.

HON HAMN has in-house Class 50,000 Cleanroom for assembly service. We collect various of parts (house made or supplied) and assemble with skilled teams and technology under ISO:9001 SOP to the finished component. All processes are under our QA team with relevant testing and inspection systems.

| Q1 |

Are you trading company or factory ?

Are you trading company or factory ?

HON HAMN's Headquarter and R&D Dept. is located in Taiwan, and Our Factory is located in Dongguan, GuangDong Province, China. |

| Q2 |

How can I ensure my technical information and know-how will be protected?

How can I ensure my technical information and know-how will be protected?

We can sign NDA's agreement (Non-Disclosure Agreements) to restrict the usage and additional disclosure of the shared information, knowledge, or materials. |

| Q3 |

I have an idea/ sample but don’t have drawing, what can I do?

I have an idea/ sample but don’t have drawing, what can I do?

Please share the project detail to us, and we can provide ON STOP SERVICE. |

| Q4 |

What type of files can you accept?

What type of files can you accept?

STP, IGS, DWG, DXF. |

| Q5 |

Your trading terms ?

Your trading terms ?

EX-WORKS, FOB, CIF, DDP, DDU |

| Q6 |

Your payment terms ?

Your payment terms ?

For plastic injection molds and metal stamping dies : 30% T/T in advance before starting design & 70% T/T before shipment. |